MARINE LIGHTING INSTALLATION

BEST PRACTICES

Vision X marine products are designed for the harsh environments surrounding marine applications. By observing the following guidelines for installation and care, Vision X marine rated products will provide long-lasting performance.

SEALING

For all marine applications, it is important to seal all mounting holes and wiring pass-throughs on the exterior of the mounting surface. Marine-grade sealants such as 3M 5200 or an equivalent should be applied to holes or cutouts that penetrate the mounting surface. Whenever possible sealants should also be applied to the interior of any protrusions after the light is installed with the proper hardware.

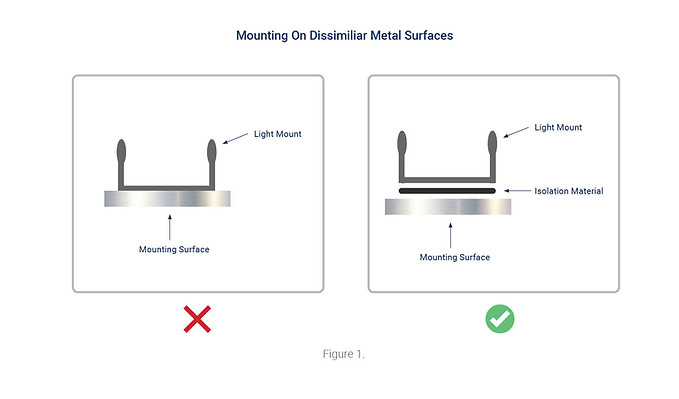

MOUNTING ON DISSIMILAR METAL SURFACES

Mounting the light housing on dissimilar metal surfaces in marine or saltwater applications can promote galvanic corrosion and possibly void the warranty.

Dissimilar metal galvanic corrosion is an electrochemical process that destroys metal, reducing its thickness and strength. This kind of metal corrosion is also strongly linked to cracking paint and coating separation.

Use the correct model and light housing/bracket material for the application.

-

Use an aluminum housing/bracket for non-ferrous applications such as aluminum, fiberglass, and wood.

-

Use a steel or brass housing/bracket for ferrous applications such as steel.

Dissimilar metals such as steel and aluminum mounted together are prone to galvanic corrosion and it is important to select the appropriate light housing material and if necessary, take steps to isolate the surfaces.

Depending on the mounting surface material, light housings and mounting hardware may need to be isolated from the mounting surface. Mounting screws can be coated with marine anti-corrosion compounds such as Tef-Gel, Eck, or an equivalent. Plastic, rubber, or isolation tapes can be placed between the mounting surface and the light housing.

When installing Vision X lighting on bottom painted surfaces, especially in submerged applications, it is recommended that the light housing be coated with the same coating material as the mounting surface. Maintain the coating on the light housing as recommended by the coating manufacturer.

PROPER ELECTRICAL GROUNDING

Always follow approved standards and use proper procedures when wiring Vision X marine products. It is important that lights are always properly grounded and appropriate procedures are followed for marine applications. If unsure of proper procedures or standards consult a qualified marine electrician for guidance.

LIGHT MAINTENANCE

Inspect the light and light housing material yearly for any signs of corrosion or leakage. Build-up of debris or biomaterials, such as plant life, can damage the seals in the light housing over extended periods of time and allow moisture to enter the housing. Clean the surfaces thoroughly and provide any necessary isolation methods if corrosion is detected.